Why is Monitoring Grain post-harvest important?

As we arrive at the later stage of the harvest period, we thought we would give you a quick guide as to why monitoring your grain post-harvest is important (and to stop all your hard work going to waste!)

As your Grain moves from the field, to store, to final sale it’s important to keep an eye on any changes that may occur due to the variable nature of grains within a bulk store. Monitoring moisture and protein levels as well as inspecting for defects, impurities and mycotoxin levels is vital to ensure you get the best price for your harvest!

At Calibre, we understand that the post-harvest period is just as important as harvest itself and have put together a list of essential testing equipment to help!

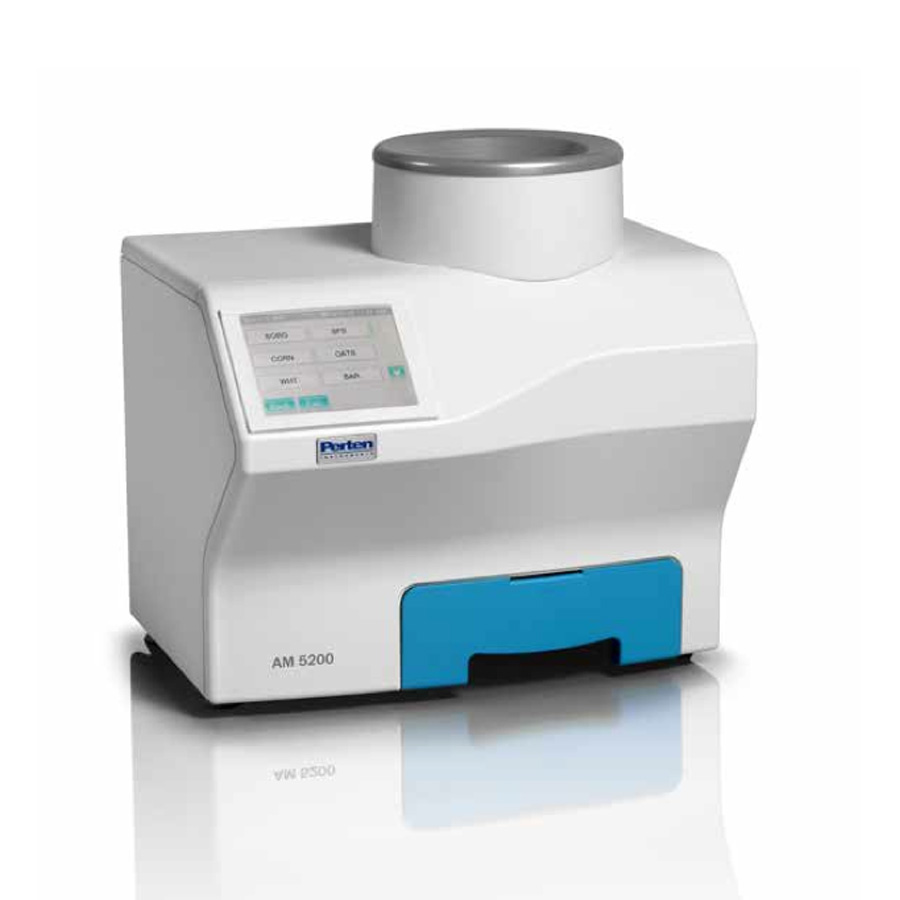

1. Grain Moisture Testing

The moisture content of your grain from the field and in store is critical. If it is too high, there is a risk of quality reduction or even crop loss. Alternatively, over drying is wasteful and will lead to reduced returns. The Perten AM5200 is a moisture meter that predicts moisture %, specific weight and temperature within a matter of seconds. Superior accuracy and repeatability are obtained using 150 MHz measurement cell made of robust, high precision die-cast aluminium.

2. Mycotoxin Testing

Testing for mycotoxins is particularly important during the storing stage as temperature and conditions change – encouraging toxins to grow. There are legal limits for mycotoxins in grain intended for human consumption and guidance limits for feed grain. Our Charm mycotoxin test kits enable the grain owner to quickly and accurately ensure they meet these limits.

3. Protein/Nitrogen Testing

Knowing the protein/nitrogen levels of your harvest gives you so much more control over your product. Which bin to store it in? Keep it segregated from lesser quality grain and to help avoid rejections at the Mills/Merchants. It can also help you make advanced decisions, if you know the protein content of your harvested crops you can decide if you need to adjust the nitrogen levels in the soil. With precise use of fertilisers you get maximum yield and quality with minimum outputs. Our GrainSense technology, is the first truly portable and affordable instrument giving farmers the these capabilities. In under 30 seconds you will get a moisture, Protein, Carbohydrate and Oil prediction using a very small amount of sample.

4. Grain Inspection

Monitoring the physical state and checking for any pests in your grain is hugely important, especially when in storage. Broken or sprouted grains will result in lower yields and can also reduce Hagberg Falling Number to unacceptable values resulting in a rejection. Our Tagarno digital system is the perfect tool for rapidly inspecting your grains for defects or contamination. The full HD live image not only has ergonomic benefits for staff but also the chance to save images and zoom into samples to show other staff members.

All in all, we think testing post-harvest is just as important as harvest itself! Here at Calibre we are experts in testing solutions all the way through the production line. If you have any questions regarding post-harvest technology, please get in touch with Ben on 01925 860 401 or info@calibrecontrol.com